Product Details

Adhering to the design of "bright as arrows, soft as feathers", each frame is hand-made, the shape is simple, with sharp edges and perfect details.

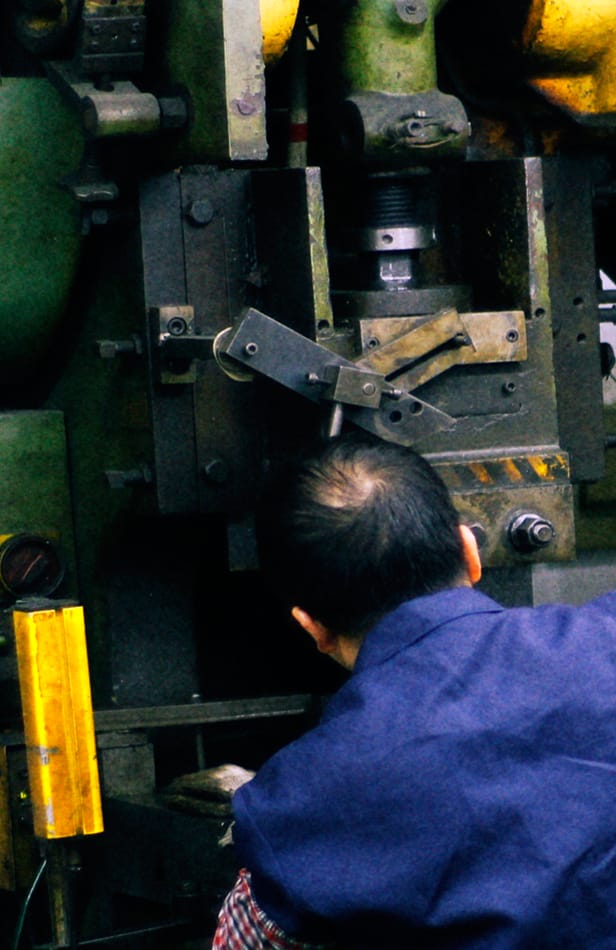

From the original design drawing to the engineering drawing, every detail is improved.Then three-dimensional grinding, forging, cutting, grinding, welding, polishing, rollers, electroplating, coloring, assembly, etc.,carefully create the detailed shapes of the frame to reflect the special charm of the product.

Product Innovation

Fansueyewear sprit: innovation and independent. The curiosity in pursuit of technological breakthroughs bring FANSU to a new world.

The novel design drives us to continuously improve our production equipment, get rid of the traditional restrictions of the eyewear industry, develop machines and improve processes of our production.

Product Material

FANSU focus on the research and application of titanium, the temples are formed by a method called "forging",and forging is a technique that hits and extends round lines.

The three-dimensional effect of the arrow feather design is a test of the abrasive tool technology and oil pressure technology of the craftsmen.Use 8MM B titanium round wire.Through the forging of the thickness drop limit, a powerful visual impact is achieved on each frame.

Product Technology

The production process of FANSU products takes more than 6 months.Each working procedure is subdivided and produced by independent craftsmen.

For example: thick-thin shape hydraulic craft, front-back corner-angle polishing skills and dark-light colour electroplating control, etc.The spirits of craftsmanship are presented in every exquisite working procedure.